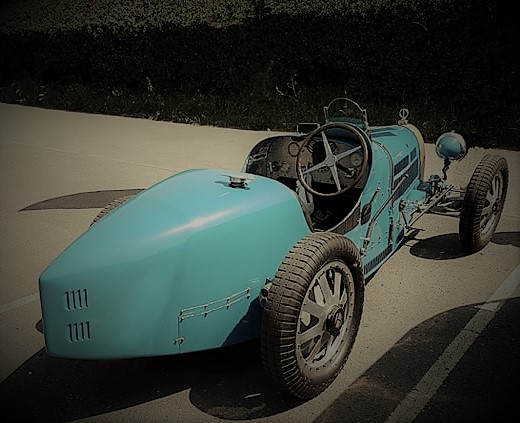

There is a real skill in up-selling a feature that costs less to manufacture. Motoring legend Ettore Bugatti was a pioneer of this art form. I have a passion for vintage cars and the Bugatti 35 has to be one of the most iconic Grand Prix racing cars ever designed. Ettore created some stunning all-aluminum cast wheels that integrated finned brake drum and 8 angled slats as spokes that promoted airflow over the brakes to assist cooling.

These wheels appeared on his racing cars but were also available as an upgrade to be supplied to customer cars instead of the standard wire wheels everyone else had. They were lighter, more elegant and very exclusive so demanded a high premium. They were also a bit more fragile but that was to be “expected” as a side effect of all the enhanced features. Decades later, it was revealed that Ettore Bugatti’s in-house foundries were very experienced and cheap compared to the cost of buying-in Wire Wheels from a dedicated manufacturer. Ettore had brilliantly saved on production costs on every car he sold with his own wheels and yet charged successfully his customers more. Fake binding is quite similar in concept.

Regular binding requires a channel to be machined on the periphery of a guitar body or neck, a binding material needs to be sourced and machined to size, and finally applied and glued in place requiring skill and time, before being cleaned up a prepped for finishing. Fake binding requires none of these steps but is all in the finishing. Of course, if you use a fancy looking maple top and it’s thick enough to be carved and leave at least a 5mm thick edge all ’round, then the result can look amazing. Historically, some guitar manufacturers, despite using very thick maple tops glued onto

To achieve the look, one way would be for the wooden body to be prepped and sealed ready for transparent

It’s a stunning look that shows off the natural woods used to their best and fullest.

For those interested in Bugatti cars and their historical background in vintage motor racing, please visit the Bugatti Trust web site and see them in action at Prescott near Cheltenham. It’s a fascinating story.

The above all Mahogany guitar has a solid Black back and metallic Amethyst top. The edge was masked off during the color coats, then cleaned, and the whole guitar was clear coated to a high gloss finish.